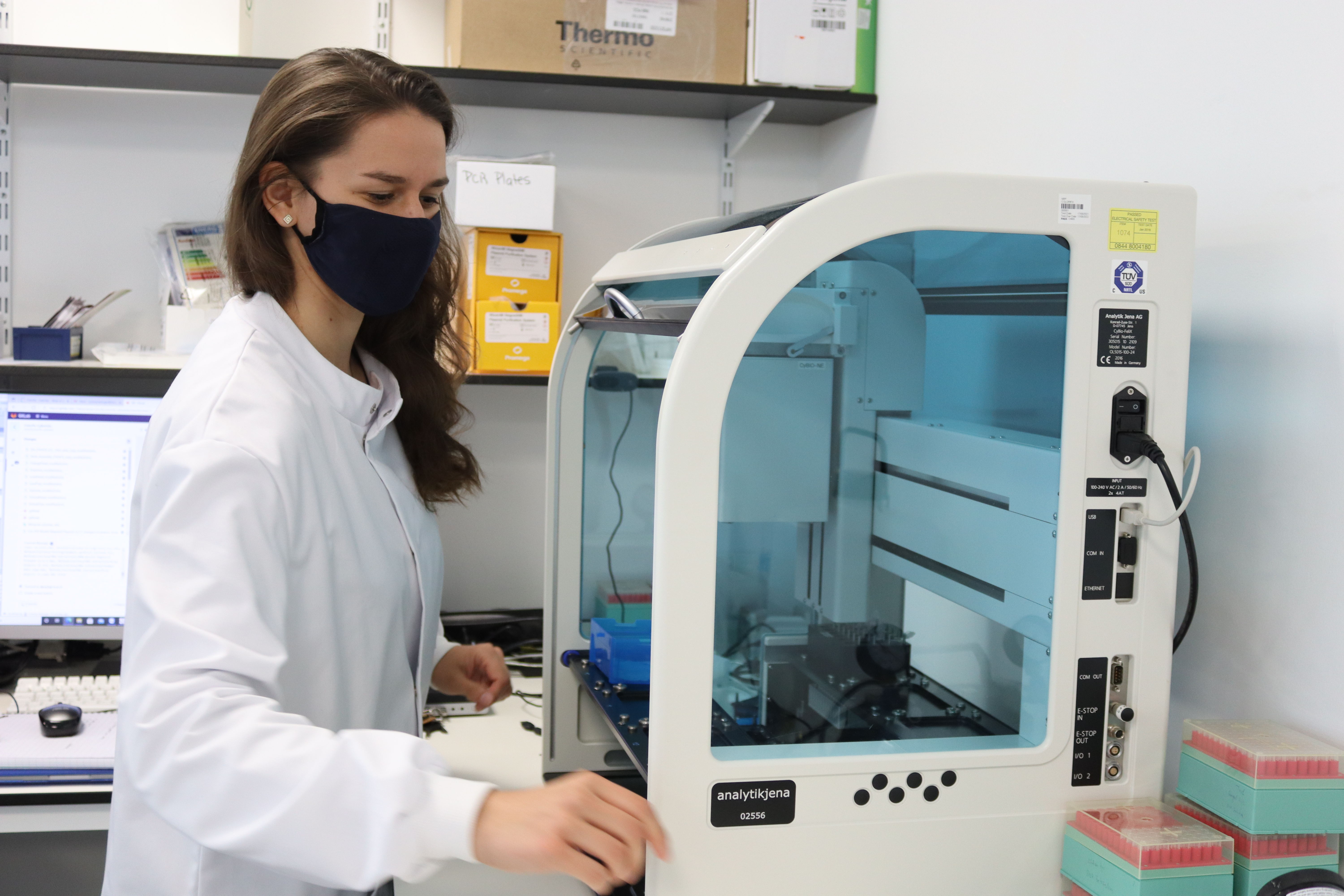

Corinna Hartinger is a PhD student at the University of Oxford and the first intern we had at Colorifix. For the last three months, she has done some amazing work between our Informatics and Microbial Engineering teams and we’re sad to see her go!

Internships are a great way for companies like Colorifix to explore high-risk, high-gain projects. On her last day, we sat down with Corinna and her lab supervisor Charlie to discuss her project, her experience working with us, synthetic biology, and more.

Tell me more about the context in which Corinna’s internship took place

Charlie: So my role, along with most others on the Microbial Engineering team, is performing strain engineering. This means genetically engineering microorganisms to produce pigments for dyeing textiles.

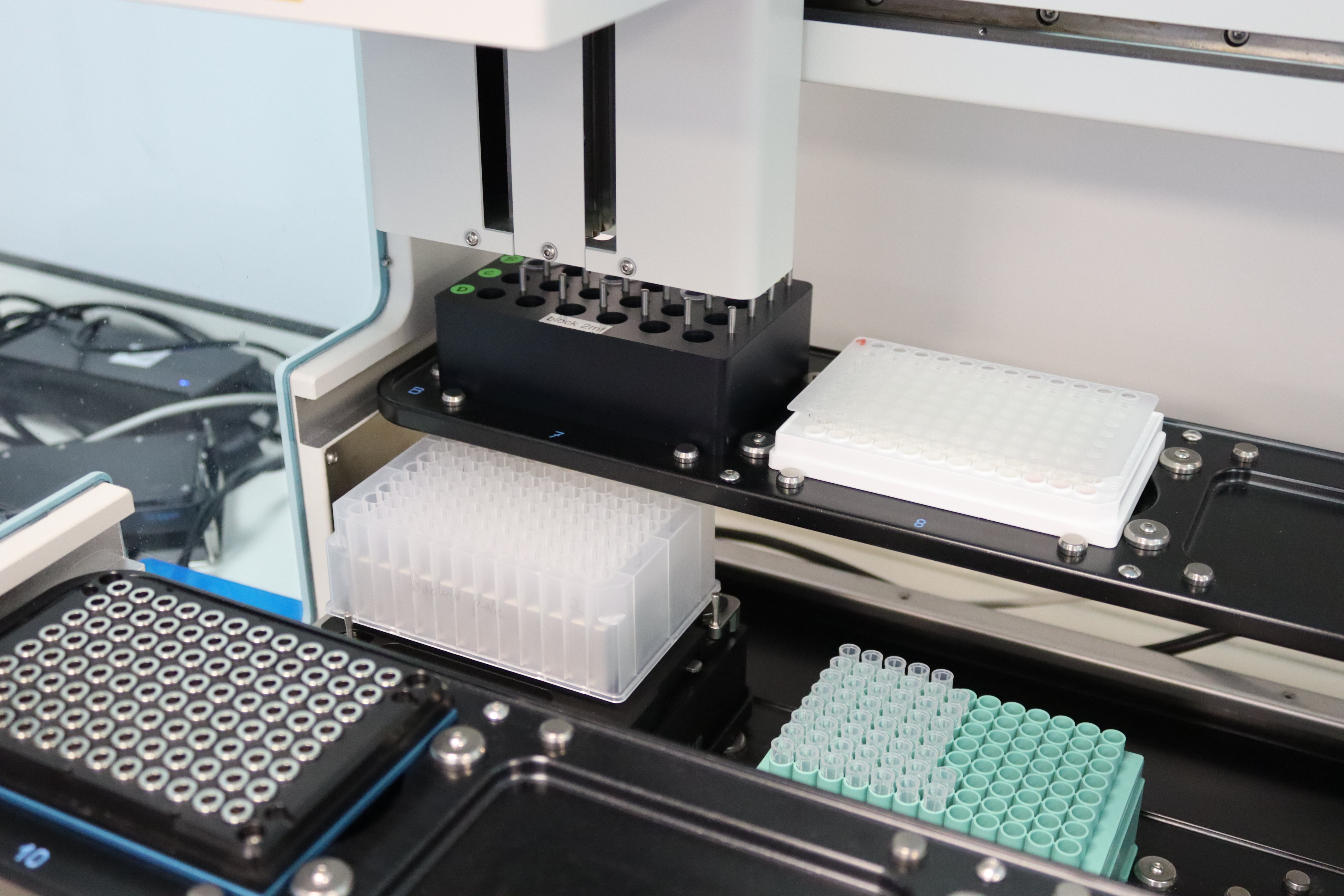

As research scientists, a large proportion of our work is taken up by manual labour— growing bacteria, assembling bits of DNA, and getting that DNA into the cells. Much of this is essentially moving small amounts of liquid from tube to tube. This takes thought and care and experience, so it’s not completely mindless, but it’s still a burden on our time which then takes away from thinking about things like: which pigments are best to use and how do we get them to work? Which approaches might work better? Or how can we make the process more sustainable?

Though Colorifix already owns a liquid handling robot and is in the process of developing workflows, when Corinna got in touch with us, we saw it as a great opportunity to accelerate the process of automating some of these important, everyday tasks.

How did you hear of Colorifix and did you have any automation experience before joining?

Corinna: As part of my PhD programme, we have to complete a three-month internship, but we can choose very freely what that internship is about.

I’m also involved in the Synthetic Biology Society at Oxford and we heard about Colorifix through our sponsor, IDT. Neil (Colorifix Head of Microbial Engineering) gave a talk to our society and I just thought, “that’s so cool, I’d really like to work with them.”

My automation experience was zero! My background is biotechnology, so I know what it’s like to do all of that tedious pipetting by hand. I have a bit of coding experience, but programming a robot was something entirely novel to me as it has its own kind of software. It was challenging and not always intuitive, but we had a lot of support from Analytik-Jena and it paid off.

Now, at the end of the internship, I’m quite confident I could make the robot do almost everything within its capabilities and it’s been really nice to see the coding have real-life outputs with liquids and plates being moved around.

You said that you realised humans are “actually pretty good robots.” What did you mean by that?

Corinna: Well, for example, when you take a tube, humans can assess how much liquid is in it; so when it’s completely full, you wouldn’t plunge the tip down to the very bottom so that it overflows— this is something the robot does very easily!

Robots need really precise instructions. When trying to programme it to move liquids between tubes, you have to think about things like, “how do I make it move further down with the tip every single time liquid is removed?” You have to calculate the exact volumes it’s taking away and how that translates to the height of the liquid in the well, etc.

With humans, you can describe a task in a general way and they’ll do it correctly. Vision, perception, and problem solving are things we’re very good at and take for granted.

So where are we now in our automation programme? What happens when Corinna leaves?

Charlie: Corinna’s work around one gene assembly protocol in particular is something we can start doing every day in the lab. When you do this protocol by hand, it’s very prone to mistakes because we’re working with tiny amounts of liquid— so this automated version will save us from the little mistakes that humans inevitably make.

This internship has been really important in helping us build momentum in a crucial and growing area of the company. For Colorifix, this is one step on a journey towards having a fully automated strain engineering pipeline – along with other automated protocols. It’s a time-consuming and expensive endeavour, but ultimately something our vision and business model requires.

Any final reflections?

Corinna: I just want to say that Colorifix is such a great example of synthetic biology doing something environmentally and socially sustainable. I can see how the general public could hear synthetic biology and be reminded of all of these bad things— “artificial”, “chemical”, or “unnatural”— but producing pigments and dyeing in a way that reduces pollutants is just an amazing example of the good synthetic biology can do. And the company seems to be trying to communicate this science so it’s not hidden away but actually something the consumer should understand and embrace.

Thank you Corinna and supervisors Neil, Charlie, and Mihails! We wish you all the best in finishing your PhD.